Quonset huts are a versatile and enduring type of structure that have been utilized since their inception for military purposes during World War II. Named after the site of their first production at Quonset Point in Rhode Island, these semi-circular steel buildings have evolved to meet a wide variety of needs in the civilian market. Today, Quonset hut kits are available for sale across various platforms, including online marketplaces like eBay. The appeal of these buildings lies in their unique blend of affordability, durability, and ease of assembly.

The design of Quonset huts allows for a high degree of customization. Potential owners can choose from different models and tailor their building with options for windows, doors, insulation, and other features to suit their specific needs. Whether for personal use as storage sheds, garages, and barns or for commercial applications, these steel structures are engineered to provide a reliable and cost-effective solution. The market offers prefabricated kits, which simplify the building and installation process, making it possible for buyers to construct their own Quonset hut with basic tools and without the need for specialized construction skills.

Key Takeaways

- Quonset huts are cost-effective and durable, suitable for various applications.

- They offer customization options to meet individual preferences and needs.

- Prefabricated kits simplify the installation process, enabling DIY assembly.

Understanding Quonset Huts

Quonset huts are notable for their distinctive arch shape and versatile use. Originating from a military background, they have evolved into structures serving various civilian purposes.

History and Design

Developed during World War II for the U.S. Navy, Quonset huts were crafted to meet the need for lightweight, easily transportable, and quick-to-assemble structures. They typically feature a semi-circular arch made of steel which defines the simplicity and durability of the design. The name ‘Quonset’ originates from the site of their first manufacture at the Quonset Point in Rhode Island.

Types of Quonset Huts

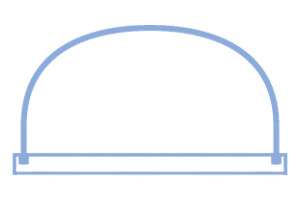

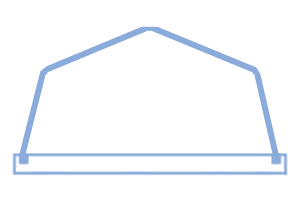

Quonset huts are predominantly available in two models: the S-Model and the Q-Model.

- S-Model:

- Features: Straight sides with a rounded top

- Ideal for: Warehousing, workshops, and industrial storage

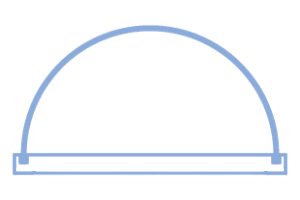

- Q-Model:

- Features: Entirely semi-circular shape

- Ideal for: Agricultural storage and smaller industrial or personal applications

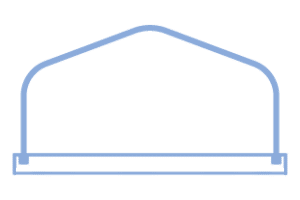

- E-Model:

- Features: Straight sides with a pointed triangular top

- Ideal for: Garage and storage

- A-Model:

- Features: Straight sides with a rounded sides and top

- Ideal for: Barns and warehouses

Both designs leverage the strength of the steel arches that comprise the buildings and can be adapted for additional customization.

Common Uses

The adaptability of Quonset huts allows for a wide range of uses. Originally purposed for military storage, these huts have since been reimagined for multiple applications, such as:

- Garages and Automotive Storage: Protect vehicles from the elements

- Workshops: Provide a robust and insulated space for various projects

- Agricultural Uses: Offer ideal conditions for storing crops and livestock supplies

- Quonset Hut Homes: Create unique, energy-efficient homes with open floor plans

They are praised for their straightforward, bolt-together construction, contributing to the ease of assembly and potential cost savings.

Benefits of Quonset Huts

Quonset huts are renowned for their durability and cost-effectiveness. Their design facilitates easy assembly, which can significantly reduce construction time and labor costs.

Durability and Maintenance

Quonset huts are engineered to be incredibly durable. Their arch-style design is resistant to extreme weather conditions, which contributes to their longevity. Maintenance for these structures is minimal due to the corrosion-resistant materials often used in their construction. The prefabricated steel not only fortifies the hut against environmental wear and tear but also simplifies routine upkeep.

Cost Effectiveness

When it comes to affordable building options, Quonset huts stand out. They are known for being cost-effective due to their prefabricated design and the reduced need for extensive labor. The standardized kits contribute to lower manufacturing costs, which in turn lowers the purchase price for consumers.

- Building Kit Package: $14-$28 per square foot.

- Concrete Foundation: $4-$8 per square foot.

- Construction: $3-$6 per square foot.

Construction and Labor Benefits

The construction process of Quonset huts brings various labor benefits. Known for being easy-to-assemble, these structures can often be built much more quickly than traditional buildings. The labor required is typically less specialized, meaning hiring costs can be reduced. An added benefit is that most of these huts come as prefabricated kits, streamlining the assembly process and eliminating many potential obstacles usually encountered in construction.

Design and Customization Options

When purchasing Quonset huts, buyers have the flexibility to select from a range of design and customization options. These metal structures offer various size specifications, styles, and exterior finishes, enabling a tailor-made solution that can meet specific functional and aesthetic requirements.

Size and Style Variations

Quonset hut kits come in multiple sizes and profiles, ensuring they can be adapted for uses spanning from simple storage sheds to expansive workshops. Typically, the sizes can vary widely, with widths often starting from 10 feet and extending to over 100 feet to suit different needs. As for height and length, these dimensions are just as flexible, allowing for planning based on volume requirements. In terms of style, Quonset huts usually feature the classic semi-circular arch profile, but they may also have straight walls to maximize internal space.

Customization Capabilities

The inherent design of Quonset huts lends itself to a high level of customization. Structures are often customizable in terms of doors and windows, where buyers can decide on the number, size, and placement to match their specific needs. The bolt-together construction facilitates this customization process, enabling alterations even after initial assembly. Furthermore, the interior can be customized with various partitions, shelves, and insulation options, making Quonset huts immensely versatile.

Exterior Finishes and Colors

Quonset hut providers commonly offer a selection of exterior finishes and colors, allowing owners to select options that best fit their environment and personal taste. The metal exteriors can come with an Energy Star-rated Galvalume Plus coating, which not only offers a sleek appearance but also reflects sunlight to help in reducing energy costs. As for colors, the range typically includes standard industrial shades that afford a professional look to the structure.

Building and Installation Process

When considering the construction of a Quonset hut, buyers can choose between DIY construction or professional assembly services. The construction process involves the assembly of prefabricated sections, ensuring rapid and streamlined building.

DIY Construction Steps

For the DIY enthusiast, Quonset hut kits come with detailed instructions that facilitate a guided and manageable build. To begin, one must:

- Prepare the site: Ensure the foundation site is clear, level, and ready for the base plates.

- Lay the foundation: Typically, a concrete slab serves as a firm base upon which the Quonset hut will be anchored.

- Assemble arches: Each arch is bolted together on the ground.

- Raise arches: Arches are then lifted and set in place successively.

- Bolt structure to foundation: Secure the arches to the base plates that are connected to the foundation.

- Install endwalls: Finish the structure by attaching the endwalls, which may include doors and windows.

- Apply insulation (optional): If desired, install insulation prior to finishing the interior buildout.

A basic Quonset hut kit should contain all necessary components, but supplemental hardware and tools might be needed. DIY builders often benefit from having an extra pair of hands, as some assembly steps may require at least two people for safety and efficiency.

Professional Assembly Services

Those preferring not to engage in DIY construction can opt for professional assembly services. Advantages include:

- Expertise: Professionals are well-versed in all construction phases, from foundation preparation to finishing touches.

- Labor: Professional services manage their own teams, obviating the need for additional help.

- Efficiency: With experience, professional teams can significantly reduce construction time.

While professional assembly introduces additional costs, some individuals may find the convenience and assurance of quality worth the investment. It is advisable for those considering this option to obtain multiple quotes and to verify the credibility of the services chosen.

Preparing for Your Quonset Hut Purchase

Before acquiring a Quonset hut, one must consider location suitability, navigate local regulations for construction, and carefully assess the financial aspects to ensure a wise investment.

Selecting the Right Location

When searching for the perfect spot, potential buyers should assess the terrain, accessibility, and the purpose of the Quonset hut. Level ground with proper drainage facilities is ideal. Accessibility for delivery trucks and proximity to the work site or home should also be considered.

Handling Permits and Building Codes

Permitting is a crucial part of preparing to erect a Quonset hut. Buyers need to research and comply with local building codes, which may dictate the hut’s size, design, and placement. Obtaining the necessary permits before proceeding is essential to prevent legal issues and fines.

Calculating Costs and Budgeting

Cost estimation is paramount in the initial stages of planning for a Quonset hut. While prices can fluctuate based on size and customization, one can expect a range from $7 to $36 per square foot. Prospective buyers should create a detailed budget considering not only the cost of the hut but also site preparation, foundation, and assembly.

- Quonset Hut Sizes and Prices (Estimation) Size (ft) Area (sq. ft) Price Range 12 x 12 144 $2,000-$6,000 24 x 12 288 Costs can vary depending on customization and specifications

Buyers should plan for potential construction costs and assess their financing options to determine the most cost-effective solution for their needs.

Quonset Hut Accessories and Features

When customizing a Quonset hut, selecting the right accessories and features is crucial. These additions not only enhance functionality but also ensure comfort and efficiency for different applications such as garages, warehouses, or workshops.

Insulation and Ventilation

Insulation is a core feature of any Quonset hut meant for habitable or temperature-sensitive storage spaces. Proper insulation options are available that cater to thermal efficiency and energy savings. For instance, one may use spray foam or fiberglass batts, providing resistance to heat flow and maintaining interior temperatures.

Ventilation systems are equally essential, especially in workshop or livestock settings, to manage airflow and prevent moisture accumulation. Options include turbine vents, which can be installed on the building’s arches, and louver vents for effective air regulation.

Doors, Windows, and Skylights

Doors for Quonset huts range from standard personnel doors to oversized garage-style doors, suitable for equipment or vehicle access. These doors come in different materials, like steel, suitable for security, or aluminum, for lighter weight.

In terms of windows, placement and size can be customized based on natural light requirements and ventilation. Skylights serve a dual purpose: inviting more daylight into the space and potentially reducing lighting costs during daytime hours.

Additional Storage Solutions

To enhance the storage capabilities of a Quonset hut, one might consider adding internal partitions or shelves. These structures are versatile, allowing for the inside to be segmented into distinct areas like offices within a larger garage or warehouse, or subdividing the space in storage sheds or workshops. The bolt-together construction can also facilitate easy expansion of storage areas as needs evolve.

Factors to Consider When Buying

When selecting a Quonset hut, potential owners need to weigh several critical factors including how it will stand up to weather conditions, the manufacturing and delivery process, and the level of post-purchase support offered by the provider.

Weather Resistance and Load Factors

Wind Resistance: It’s imperative to consider the wind resistance of a Quonset hut, especially in areas prone to high winds. US steel huts are designed to withstand significant wind speeds, but one should always verify the specific wind rating.

Snow Load: The roof structure must be able to handle snow loads. In regions with heavy snow loads, it’s crucial to ensure the hut’s design can support accumulated snow weight without risk of collapse.

Manufacturing and Delivery Considerations

Manufacturing: Quonset huts should be manufactured from high-grade US steel for optimal durability. Buyers should inquire about the manufacturing process and the quality of materials used.

Delivery and Shipping: Understand the details of delivery and shipping. Costs can vary, and the time frame for delivery should align with the project timeline. Upon ordering, confirm whether the price includes full delivery to the site location.

Post-Purchase Support

Support and Consultation: Comprehensive post-purchase support ensures that any issues can be swiftly addressed. Providers should offer a clear line of communication for consultation and assistance during assembly and installation.

Maintenance Advice: Reliable suppliers typically extend ongoing maintenance advice, helping owners preserve the hut’s integrity over time. Always ask about the availability and scope of their customer service.

Each of these subsections is focused on ensuring the buyer makes an informed decision that leads to the acquisition of a Quonset hut suited to their specific needs.

Frequently Asked Questions

In searching for Quonset huts for sale, buyers often have key concerns about aspects such as cost, customization, and regulatory compliance. This section addresses these common inquiries.

What factors should be considered when purchasing a used Quonset hut?

When purchasing a used Quonset hut, buyers should examine the structure’s integrity, the type of steel used, its previous use, and whether it meets current building codes and load requirements. They should also assess the cost of transportation and potential renovation needs.

How do the prices of Quonset hut kits vary by size and manufacturer?

The prices of Quonset hut kits can vary significantly depending on the size of the structure and the manufacturer. Factors such as the thickness of the steel, additional features, and the complexity of the design also influence the cost.

What potential drawbacks should one be aware of before investing in a Quonset hut home?

Potential drawbacks of Quonset hut homes include limited customization options for windows and doors due to the curved structure, potential challenges with insulation, and the uniqueness of the building style which might not appeal to all.

Are there any specific regulations to keep in mind when installing a Quonset hut in residential areas?

Specific regulations for installing a Quonset hut in residential areas may include zoning laws, building codes, and neighborhood covenants. It’s important to obtain the proper permits and ensure compliance with local requirements before installation.

What are the structural benefits of Quonset huts compared to traditional buildings?

Quonset huts offer structural benefits such as resistance to extreme weather, durability due to high-quality steel construction, and the absence of interior columns providing unobstructed internal space. They are also known for their quick assembly and cost-effectiveness.

Can Quonset huts be customized to fit specific design preferences or functional needs?

Customization of Quonset huts is possible, allowing buyers to choose from a variety of sizes, door types, and window configurations. Additional custom features can include skylights, ventilation systems, and various exterior finishes to fit specific design preferences and functional needs.