The design of a Quonset hut allows it to withstand severe weather, thanks to its arching form and sturdy all-steel construction. This durability makes them an optimal choice for businesses situated in areas prone to harsh climatic conditions. Businesses appreciate the straightforwardness of assembling a Quonset hut, which often involves bolting together corrugated steel arches, making them a viable option for companies looking to expand without extensive construction costs or time commitments.

As commercial spaces, Quonset huts offer versatility. Their clear span interiors provide column-free spaces, allowing maximum usable area for various commercial operations. This design efficiency paired with the cost-effectiveness of their materials positions Quonset huts as a practical solution for many business owners seeking reliable and long-lasting commercial properties.

Design and Structure

In commercial Quonset huts. Their iconic shapes aren’t just for show; they serve distinct structural purposes, being engineered for durability and ease of assembly.

Arches and Clear-Span Design

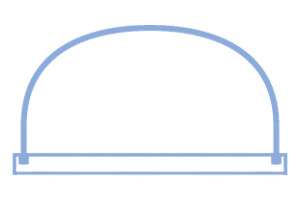

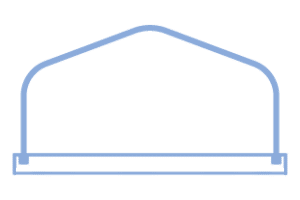

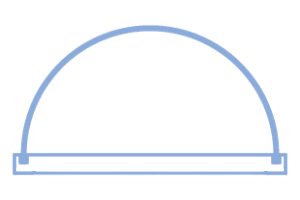

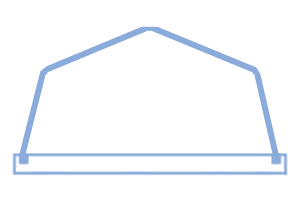

Quonset huts are recognized for their characteristic arches that span the full width of the structure. This clear-span design is free of internal columns, maximizing the usable space inside. Arches not only provide architectural strength but also allow Quonset huts to withstand harsh weather conditions.

Material Composition

These structures are typically made of galvanized steel, a material chosen for its resistance to corrosion. The steel is often corrugated, a feature that enhances its durability and strength. With the right treatment, this material remains resilient against environmental factors.

Prefab Building Process

Quonset huts are prefabricated structures, meaning their components are manufactured offsite and then assembled at the final location. The prefab process includes:

- Pre-measured and pre-drilled panels: These ensure a smooth building process.

- Easily bolted together: The arches are assembled on the ground before being raised.

- Repetition of arch assembly: This consistent approach guarantees structural integrity.

By employing a modular design, these buildings can be erected quickly, often without the need for specialized construction equipment.

Benefits of Quonset Huts for Business

Quonset huts provide businesses with a practical solution for their structural needs, offering a balance between cost-efficiency and durability. These steel buildings cater to a variety of uses due to their easy assembly and customizable design.

Affordability and Cost-Effectiveness

Quonset huts have a reputation for being affordable and cost-effective. The manufacturing process ensures that the steel components are pre-cut and drilled, which reduces the need for expensive onsite labor. By simplifying construction, businesses save on both materials and labor costs.

- Affordable materials: Standardized parts lower production costs.

- Reduced labor expenses: Simple assembly decreases the need for skilled labor.

Durability and Maintenance

The durability of Quonset huts is another significant advantage. Constructed from high-quality steel, these buildings are designed to withstand extreme weather and resist rust. This strength translates to minimal maintenance requirements, saving businesses on long-term upkeep expenses.

- Weather-resistant: Engineered to endure harsh conditions.

- Low maintenance: Steel’s longevity reduces the need for repairs.

Ease of Assembly

Ease of assembly makes Quonset huts particularly attractive for businesses. Their design allows them to be quickly constructed with basic tools, eliminating the necessity for professional contractors. This feature translates to businesses being able to utilize their Quonset hut in a shorter timeframe.

- Pre-cut components: Simplifies on-site assembly process.

- Simple construction: Businesses can often self-assemble with minimal training.

Customization and Versatility

Customization and versatility are integral to Quonset hut designs. They can be customized to fit various business requirements, from storage sheds to retail spaces. The clear span design also means there are no internal supports, providing a versatile open space that can be utilized in multiple ways.

- Adaptable layouts: Internal spaces can be designed to meet specific needs.

- Multiple uses: Suitable for workshops, offices, and storage, among others.

Commercial Applications

Quonset huts adapt flexibly for various business needs due to their sturdy steel construction and easy-to-assemble arch design. They’re particularly effective for spaces like warehouses and agricultural buildings, retail shops, and casual eateries, as well as professional offices and robust workshops.

Warehousing and Storage

Quonset huts serve as durable warehouses for businesses needing ample storage. Their clear span design allows for maximum use of interior space, with no need for supporting columns. They are ideal for storing large equipment, inventory, and can be customized for specific warehousing needs.

Agricultural Use

These structures are highly valued in the agricultural sector for their resilience and versatility. They can house livestock, store farm machinery, and protect produce and grains. Their climate-resistant features make them suitable for use as barns and greenhouses.

Retail and Restaurants

With their distinctive semi-circular shape, Quonset huts attract attention, making them suitable for retail stores and restaurants. They provide a unique shopping and dining experience, can be designed with an open floor plan, and have custom frontages to welcome customers.

Offices and Workspaces

For businesses, Quonset huts can be transformed into modern offices and comfortable workspaces. They’re easily insulated and can be partitioned, offering a combination of private and open-plan areas, ideal for dynamic office environments and co-working spaces.

Garages and Workshops

A Quonset hut’s strength and security make it perfect for use as a garage or workshop. They can protect vehicles and machinery from extreme weather and unauthorized access. Their spacious interior is also ideal for workshop activities, from automotive repair to creative projects.

Construction Considerations

When constructing a commercial Quonset hut, one must meticulously navigate building codes, lay a solid foundation, and secure adequate insulation and weatherproofing to ensure the structure stands the test of time and elements.

Building Codes and Regulations

Local building codes are the rulebook for construction and are crucial in ensuring the safety and compliance of a Quonset hut. It’s important to consult with local authorities to understand and adhere to the local building codes. These regulations may dictate limitations on the size, location, and use of the building, among other aspects.

- Check zoning laws: Confirm the property is zoned for commercial use.

- Obtain permits: Secure all necessary building permits before construction begins.

Foundation and Site Planning

A solid foundation is the bedrock of any Quonset hut. Proper site planning and preparation of the foundation will affect the longevity and stability of the structure. For a Quonset hut, the foundation usually involves concrete slab, piers, or footings, depending on the size and use.

- Assess the land: Ensure the site is free of drainage issues.

- Choose the right foundation type:

- Slab foundation for industrial use.

- Pier or footing foundations for smaller structures.

Insulation and Weatherproofing

Effective insulation and weatherproofing are vital, given the Quonset hut’s characteristic steel construction. They protect against weather conditions such as extreme temperatures, humidity, and condensation.

- Insulate walls and roof: Use batt or spray foam insulation for better energy efficiency.

- Seal the structure: Apply weather-stripping and sealants to prevent leaks and drafts.

Customization Features

Commercial Quonset huts stand out for their flexibility in design. They cater to a range of business needs, allowing for tailored solutions in expansion, and interior and exterior design.

Windows and Doors

Adding windows and doors is a simple yet effective customization for Quonset huts. These structures can incorporate various types and sizes, providing natural light and access that meet specific operational requirements.

- Windows:

- Custom sizes for natural lighting

- Placements can vary to suit workflow

- Doors:

- Personal and garage-style doors for different uses

- Can be placed in endwalls or sidewalls

Interior and Exterior Finishes

The interior and exterior finishes of a Quonset hut can be tailored to match the branding and functional needs of a business. They offer an array of colors and finishing materials, presenting not only a professional appearance but also additional protection against the elements.

- Interior:

- Insulation options for climate control

- Partition walls to create distinct workspaces

- Exterior:

- A variety of color choices

- Different coatings for corrosion resistance

Expansion Potential

As businesses grow, their spaces often need to scale up. Quonset huts excel in this area, designed to be expanded easily. One can lengthen the structure to accommodate more operational space or increase storage capacity.

- Expansion features:

- Extendable endwalls for simplified enlargement

- Modular design elements for adding sections

Purchasing and Assembly Guide

When embarking on the purchase and assembly of a commercial Quonset hut, one must consider their budget, the right size and model for their needs, and understand that it’s a prefabricated steel structure which greatly simplifies the process. Manufacturers often provide a step-by-step guide to aid in assembly. It’s important that these instructions are followed meticulously to ensure proper construction.

Choosing the Right Model and Size

One must first determine the appropriate model and size of the Quonset hut to suit their specific needs. Sizes vary, and they should correspond to the space requirements of the individual or business. Considerations include:

- Intended use: Storage, workshop, office, etc.

- Available space: Measurements of the site.

- Budget: Higher costs for larger sizes.

A table of common sizes might look something like:

| Width | Length | Height | Suitable for |

|---|---|---|---|

| 20′ | 40′ | 12′ | Small workshops, storage |

| 40′ | 60′ | 16′ | Medium businesses |

| 60′ | 100′ | 20′ | Large industrial projects |

Assembly Instructions

The next step after the acquisition of a Quonset hut is the assembly process. These structures often come with pre-drilled holes and a step-by-step guide to streamline the process. The general steps include:

- Foundation preparation: This may involve pouring a concrete slab or setting up railway ties.

- Arch assembly: Erecting the arched sections that make up the structure.

- Bolting: Securing the sections together using bolts, which are usually pre-aligned with the pre-drilled holes.

- Endwalls installation: Attaching the endwalls to enclose the structure.

Potential Challenges and Solutions

Adapting to Various Environments

Commercial Quonset huts are renowned for their strong structural integrity, capable of withstanding harsh weather conditions such as heavy snow loads, extreme winds, and even seismic activities. Nevertheless, adaptation to varied climates can pose a challenge.

Solutions to consider:

- Reinforcing Structures: In areas prone to high winds or heavy snow, additional structural reinforcements can be introduced.

- Insulation: Proper insulation helps maintain a stable internal environment, crucial in extreme temperatures.

Meeting Commercial Needs

Understanding that each business has unique needs is vital in constructing a Quonset hut that delivers sufficient usable space. The pre-fabricated nature of these buildings offers flexibility but may require customization to align with specific commercial functions.

Solutions to consider:

- Customization: Modifying the interior layout to create an optimal workflow and accommodate necessary equipment.

- Expandability: Design the hut with future expansion in mind to easily increase space as the business grows.

Frequently Asked Questions

How can you customize the interior of a commercial Quonset hut?

The interior of a Quonset hut can be customized to fit various business needs. They can be outfitted with shelving, partitions, and even mezzanines, depending on the required functionality.

Are there different styles or models of commercial Quonset huts available?

Yes, commercial Quonset huts come in several styles, including the traditional semi-circular design as well as modified versions with straight walls known as ‘straight-wall models’ that offer different interior space dynamics.

What should be considered when selecting a location for a commercial Quonset hut?

When selecting a location for a commercial Quonset hut, one should take into account the ground conditions, accessibility, local building codes, and zoning regulations, along with the hut’s intended purpose.

How do Quonset huts fare in extreme weather conditions?

Quonset huts are known for their resilience in extreme weather, including heavy snow, high winds, and even earthquakes. Their aerodynamic shape and sturdy construction materials contribute to their ability to withstand harsh conditions.