Constructing a Metal Quonset Hut

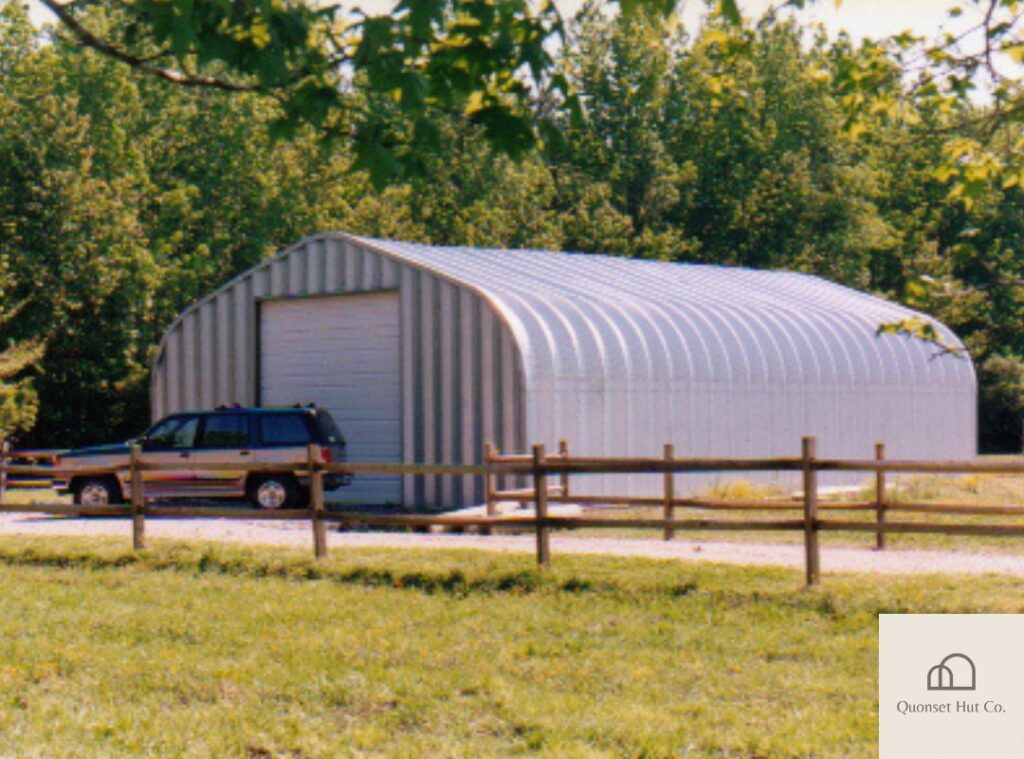

Steel Quonset huts are renowned for their simplicity in assembly and durability. Arrival of the building components is typically consolidated onto one or two pallets, and the construction process begins with the foundational stage, followed by a series of steps towards completion.

Laying the Foundation

The foundation is paramount for the stability of your Quonset hut. Concrete foundations are common, and they are usually a 4-inch thick floating slab or a perimeter foundation which the hut will be affixed to.

Foundation Types:

- Trough/Keyway Foundation: This entails an 18-inch wide and 16-inch deep footer with a 3.5×9 inch channel at a 1″ slope.

- Slab Foundation with Base Connectors: Utilizes a floating slab with C-channel base connectors, eliminating the need for a channel.

Planning Phase

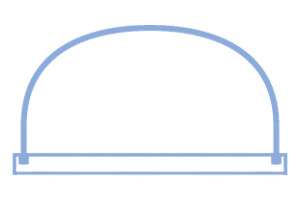

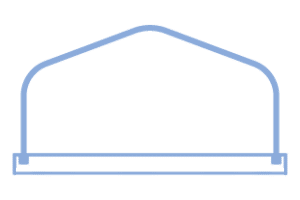

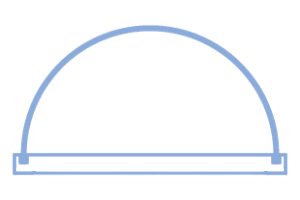

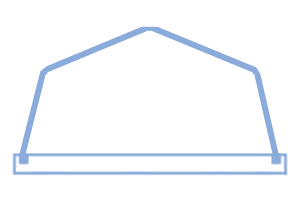

During this stage, selection of the Quonset hut design, which can be Q-, S-, or P-model, occurs. Their dimensions and architectural style play a critical role, as these determine space and facilities within. Additionally, your chosen height should cater to its intended use, typically within a specific range depending on the model.

One must also navigate building codes, permits, and zoning regulations to ensure compliance. The construction site must be evaluated for soil stability and drainage. For structural integrity, consulting a structural engineer for site analysis proves beneficial.

Design Considerations

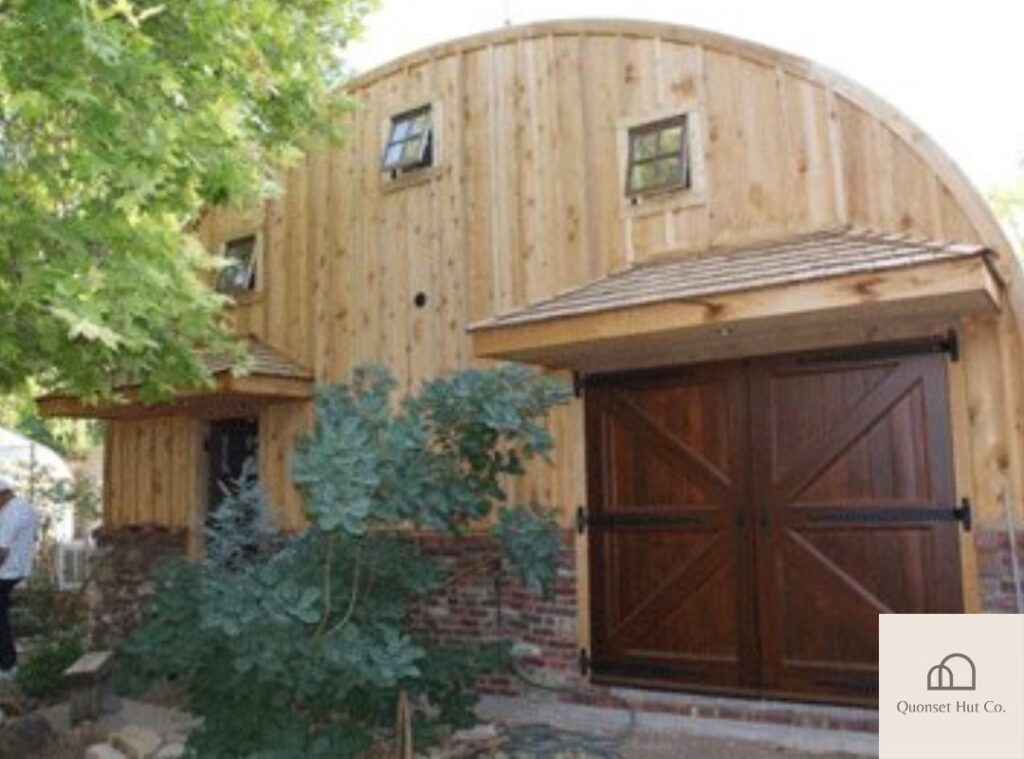

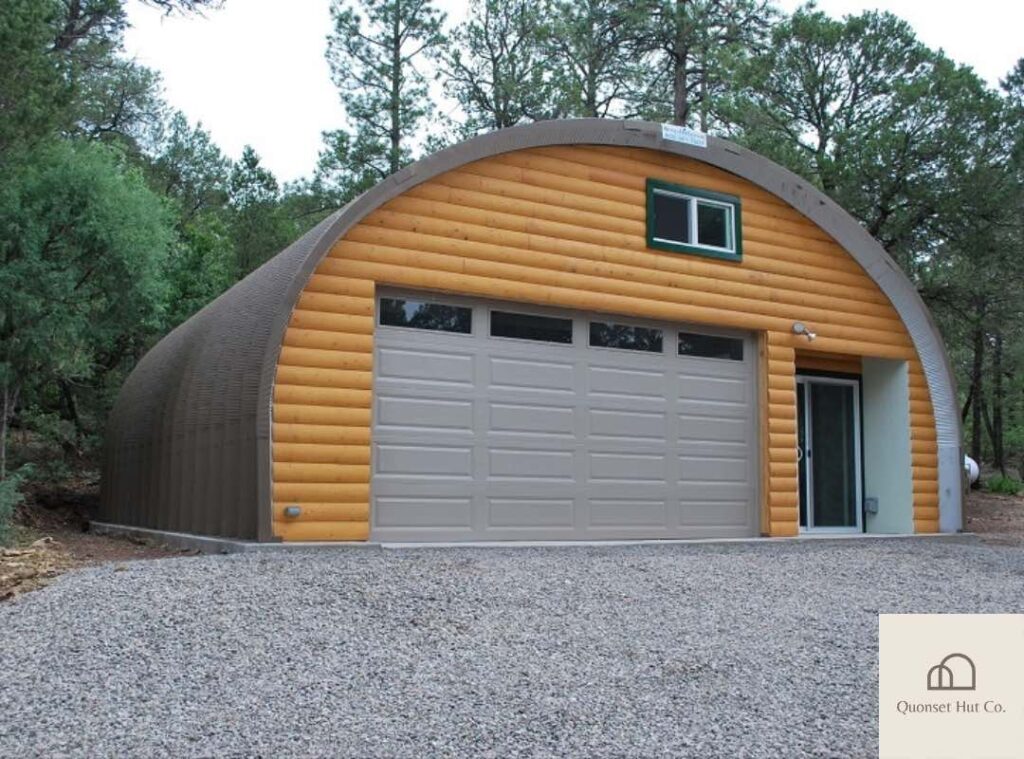

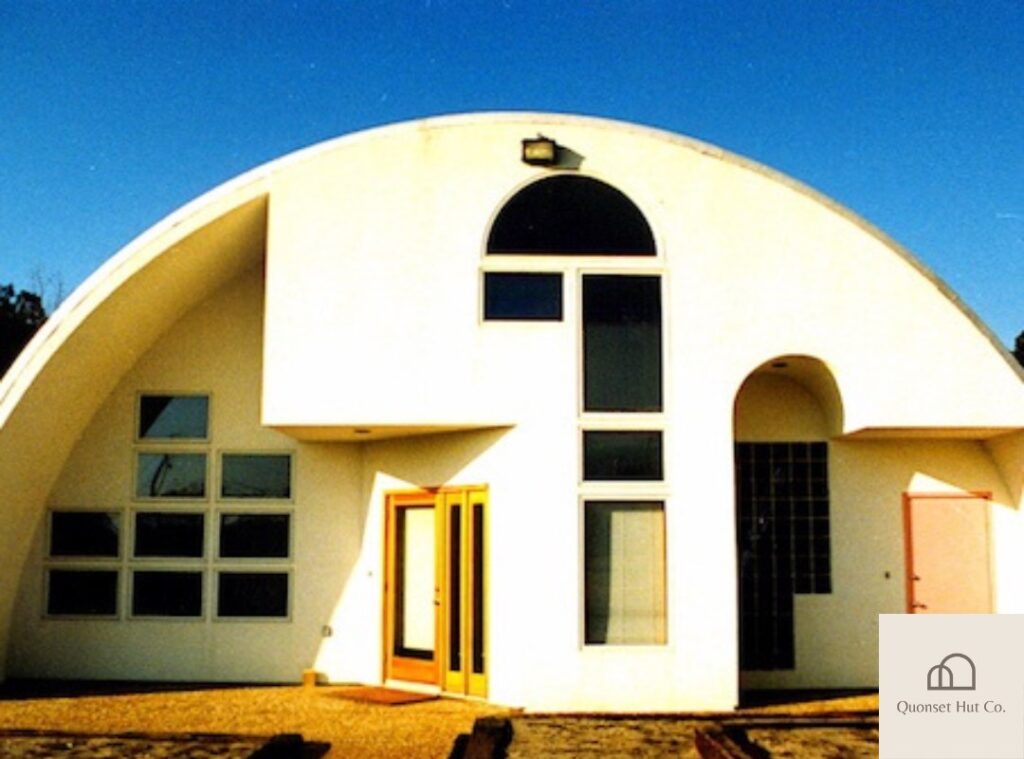

When customizing your Quonset hut, options might include windows, doors, and ventilation systems. Apart from functional aspects like doors and skylights, aesthetics such as pre-assembled end walls can also be selected. The design phase attaches cost implications, particularly when customization plans influence the structural design.

Common Upgrades:

- Pre-assembled end walls

- Various door types

- Skylights

- Ventilation units

Ordering Your Kit

Upon defining the structure’s specifics, obtaining various quotes from suppliers is advisable. A down payment is required to initiate the engineering process of your custom building. It’s essential to inquire if the quoted price includes end walls, as some suppliers may consider them additional features.

Pre-Construction Steps

Preparation of the site follows:

- Site clearing: Removing obstructions and planning the setup for utilities.

- Soil testing: Ensuring the ground can support the hut.

- Grading and compacting: This should align with the site plan needed for permitting purposes.

- Insurance: Builders’ risk insurance is advisable prior to construction.

With the foundation ready, one can proceed with the assembly of the Quonset hut. The assembly requires arch panels to be secured to the foundation through anchor bolts and grouted for a watertight seal.

Flooring Options:

- Concrete: For heavy use, a 6″ slab may be necessary.

- Plywood or Wood Flooring: These can be employed for light-duty applications.

Quonset huts designed for DIY construction should only be erected by individuals with the requisite knowledge or under professional supervision.

Quonset Hut Expense Analysis

Quonset huts serve as a cost-effective building solution, with expenditures varying based on size, customization, and location. If you are looking to buy a quonset then this is how much it will cost you to purchase it, as well as everything else.

- Building Kit (Shell): Typically ranges from $14 to $28 per square foot.

- Foundations: Essential for stability, costs fall between $4 to $8 per square foot.

- Construction: Erecting the structure may cost from $3 to $6 per square foot.

- Interior Finishing: Although optional, these expenses start at $10 and can extend over $100 per square foot.

Installation Considerations

Installation Considerations: The installation process for a Quonset hut involves several steps and considerations:

- Site Preparation: The site must be cleared, leveled, and properly graded before the foundation is laid. Proper drainage is also essential to prevent water from pooling around the structure.

- Assembling the Arch Building Panels: Quonset huts are typically made of arched steel panels that need to be bolted together. This process usually starts from one end and progresses to the other.

- Anchoring: The structure must be securely anchored to the foundation to withstand wind and other environmental stresses.

- Endwalls and Entrances: Once the arches are in place, the endwalls are constructed, and doors and windows are installed as per the design specifications.

- Utilities Installation: If the hut will have electricity, plumbing, or HVAC, these systems are usually installed after the structure is up but before the interior is finished.

- Inspection and Compliance: Throughout the installation process, it’s important to ensure that the construction complies with local building codes and passes any required inspections.

It’s advisable to consult with a professional contractor who has experience with Quonset huts to ensure that the foundation is appropriate for your specific needs and that the installation is carried out correctly.

Lucky for you, we sell quonset huts, directly from the source so we can get you the best prices possible.